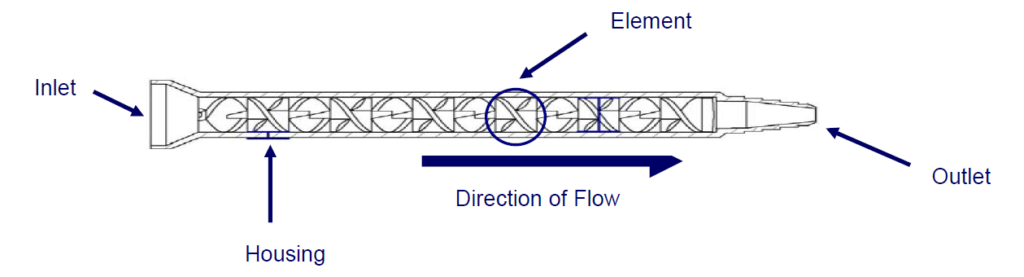

A static mixer (also called a motionless mixer or mixing nozzle) is a simple device with no moving parts, and consists of a series of internal elements (baffles) within a plastic housing (tube).

The static mixer is the central, if not the most important, part of the two-component dispensing system.

Theory of Static Mixing

Elements within the mixer stay “static” i.e. they do not move.

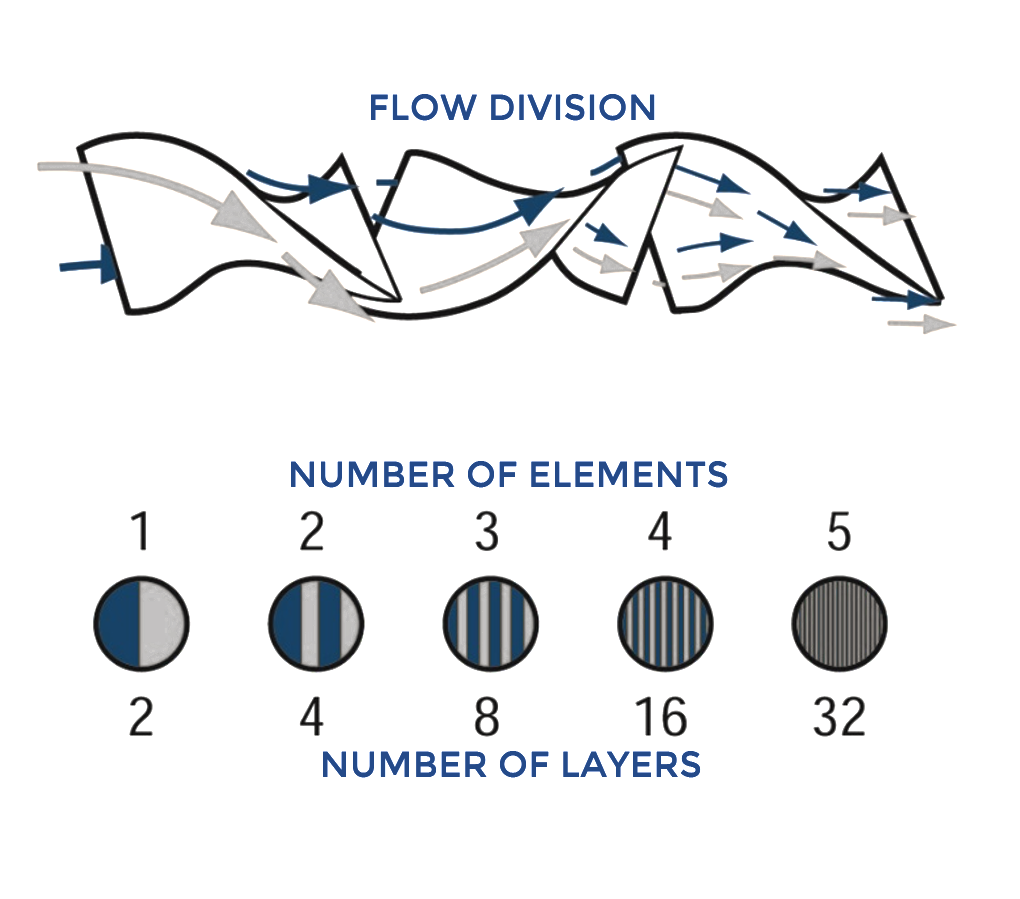

The A & B materials are pushed/pumped/injected into the static mixer in the ratio required. As the two materials move through the series of alternately-angled elements, they are forced to come together and apart, over and over again.

This flow creates layer upon layer of A & B materials. Eventually, the material has been layered so many times, that A & B become a homogeneous stream when they exit the mixer outlet.

Static Mixers optimized for specific fluid types

| Material | Typical # of Elements |

| Acrylic | 8 – 20 |

| Epoxy | 15 – 24 |

| Polysulfide | 24 – 32 |

| PU Foam | 10 – 24 |

| Silicone | 20 – 30 |

| Urethane | 24 – 36 |

| Viscosity Range | Mixing Element Diameter Range |

| Thin < 5,000 cps Thinner than syrup | 0.093” – 0.25” (2.36 – 6.35mm) |

| Medium 5,000 – 50,000 cps Thicker than honey, less than ketchup | 0.212” – 0.314” (5.4 – 8mm) |

| Thick > 50,000 cps Thicker than ketchup | > 0.366” (9.3mm) |

When mixing fluids of two different viscosities, always use the element rated for the higher viscosity

Each type of outlet delivers specific advantages for specific applications